Get Support

123-456-789-10

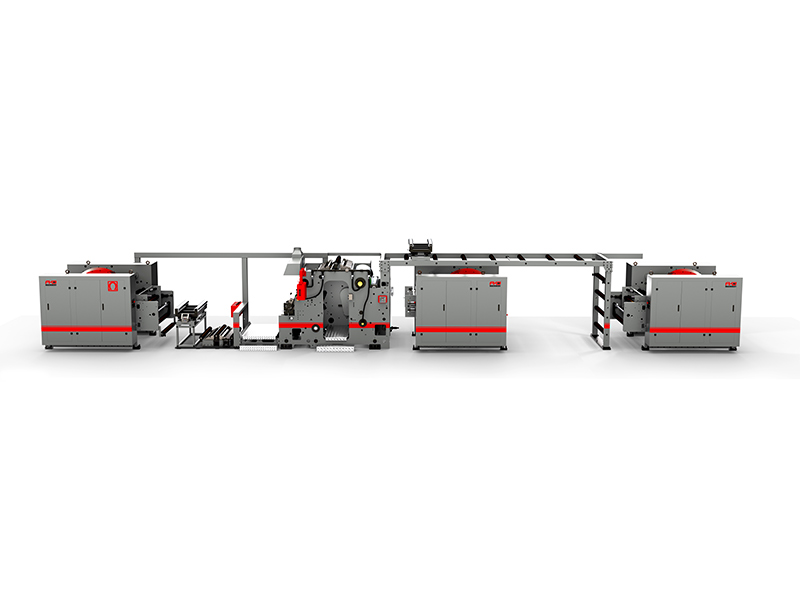

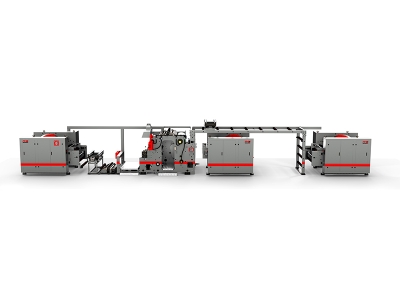

OMEGA 1600

OMEGA compound is a hot melt coating & converting equipment to meet the needs of a variety of different applications, can be different coating amount and coating viscosity, can be full-coated and partially coated. It is mainly used in consumer labels and technical tape; Can be used on liner less paper and composite materials. The combined use of OMEGA and ALPHA silicon coating lines enables the connection of production paper labels and film labels, which not only increases efficiency , innovates craftsmanship and saves materials, but also is the preferred equipment for printing companies.

Diversity Coating Unique modular coating unit design, high precision coating head, making the minimum consumption of hot melt adhesive, you can choose different slit or scratch free bar coating head, acrylic-based pressure-sensitive hot melt UV curing system.

Efficient and sustainable Self-designed automation system, regular preheating hot melt adhesive box and coating head, mobile APP real-time monitoring of machine running status.

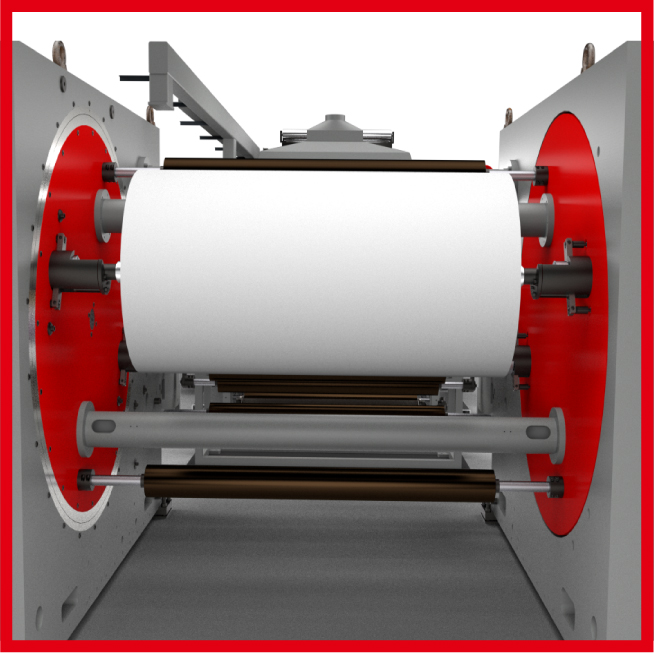

Unwinding

Unwinding

The unwinding with shear-plate is unstopped which the structure is stable and reliable. With closed-loop tension control and automatic winding diameter calculation, unmanned roll change is realized.

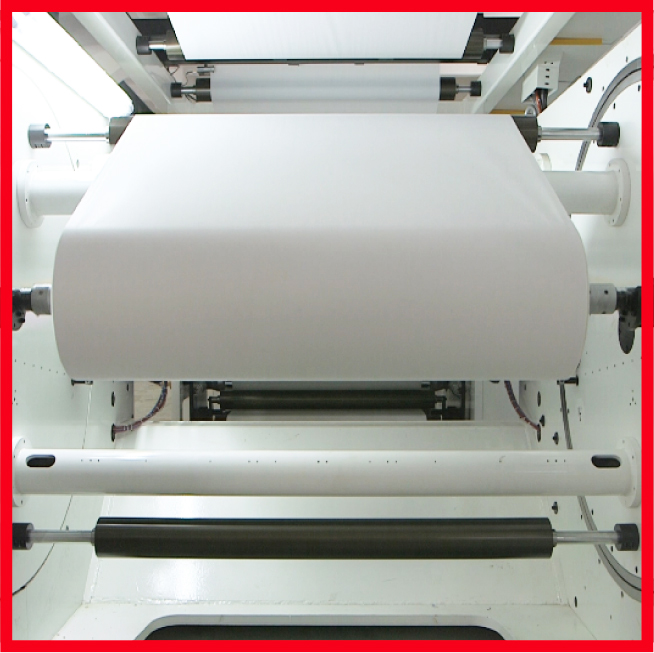

Winding

Winding

Freely switch 3" and 6" air-up shafts and the shear-plate non-stop structure realizes automatic cutting of preset length.

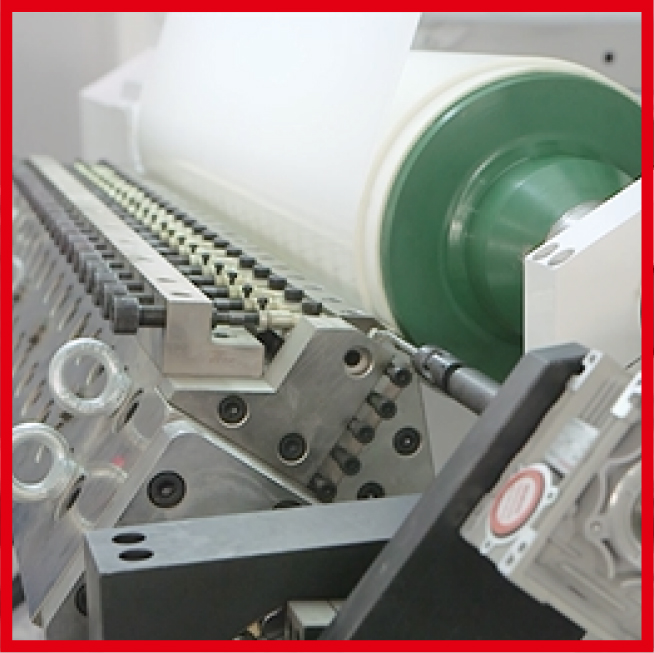

Coating Station

Coating Station

Modular designed precision coating station

Support smart mobile operation

Support smart mobile operation

Remotely access and monitor production efficiency and reduce management costs. At the same time, the client can generate production report automatically.

Simple operation

Simple operation

A human-machine interactive interface that displays all data information of the machine.

- Automatic coating and glue supply function

- Intelligent glue heating function

- Precise coating function

Intelligent human machine interface operation:

- Various non-stop winding diameter

- Multiple wind cutting modules

- Multiple finished roll handling systems

High plasticity equipment:

- Always excellent quality

- Reliability with high quality

Quality and reliability:

- Remote diagnostics and maintenance of mobile phones

- Provide lifetime upgrade service

Operational simplicity redefined:

| Max Feed Width (mm) | 1650 | ||

| Max Coating Width(mm) | 1600 | ||

| Max Unwinding Diameter | 1000 | ||

| Max Machine Speed(mm) | 300-500 | ||

| Max Winding Diameter | 1000 | Coating Weight Range | 12-25 |