Get Support

123-456-789-10

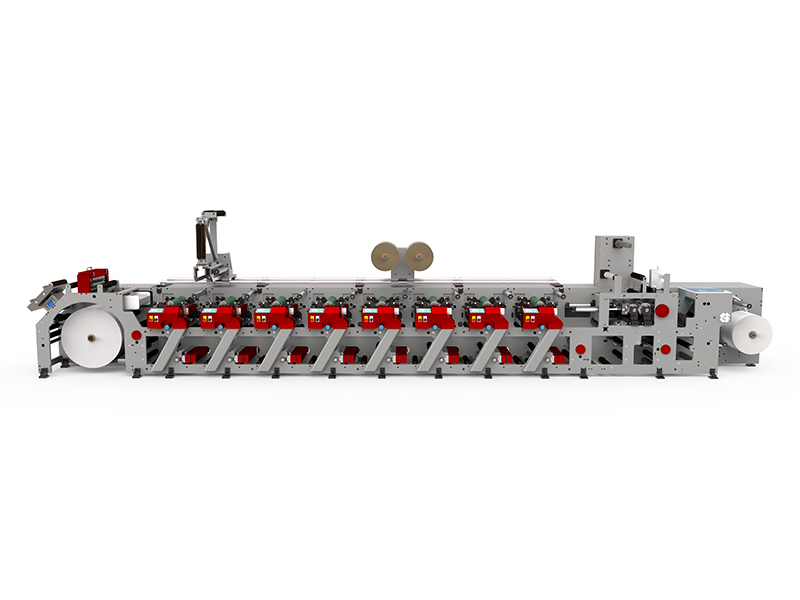

DELTA-420

DELTA 420 Flexo printing press is a kind of printing equipment which is developed by our company on the basis of absorbing foreign advanced technology experience and combining with our core technology. The press is for shipping label, adhesive material, film and other materials. The whole machine adopts three servo synchronization control, uses LED UV curing, high precision and low pollution. This machine has advanced functions, simple operation, low production cost, and can be customized according tocustomer needs.

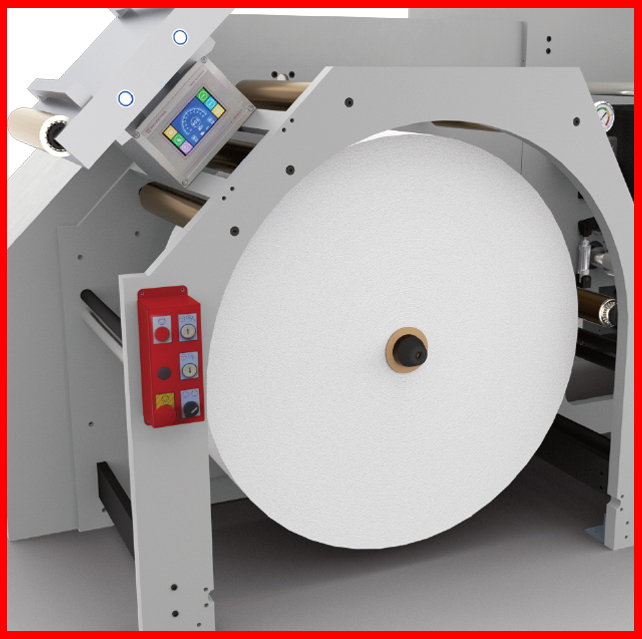

Unwind

Unwind

Our unwind unit is controlled by a closed-loop tension system insuring a constant web tension that is also crucial throughout the press and includes a hydraulic lifting system,(It also has&hellip) an integrated dust removal unit and a corona treatment system.

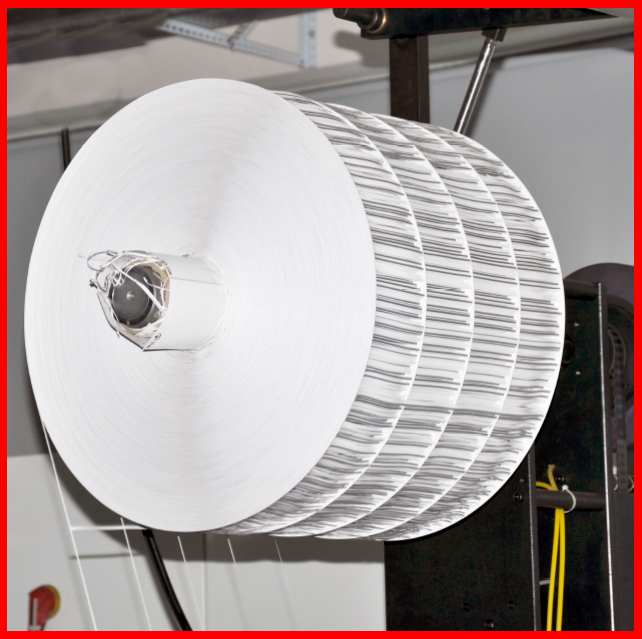

waste rewind

waste rewind

This structure is easy to waste rewind and not easy to break. It has a good performance on waste rewind of irregular and very fine waste edges, reduces the waste of downtime caused by cutting waste edges and improves production efficiency.

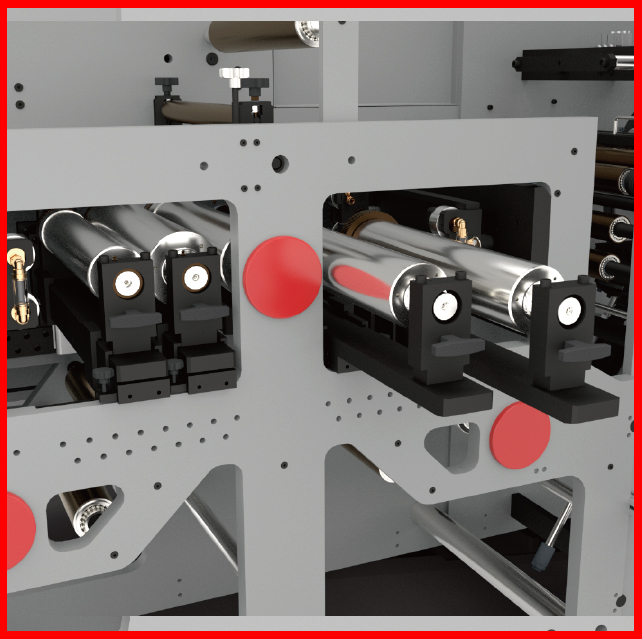

Flexo unit

Flexo unit

Reliable, precise and productive. This printing technology brings ease of use and stable printing. Using a patented printing pressure adjustment, it will deliver repeatability and high-quality printing.

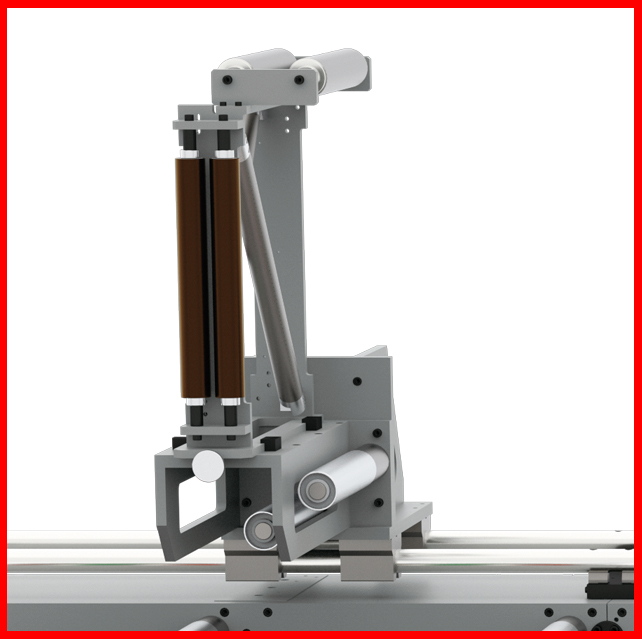

Rail system for mounting

Rail system for mounting

• Turn bar unit with an integrated lateral adjustment • Cold foil unit that can be moved to any print station • Lamination station

orizontal die cutting unit

orizontal die cutting unit

This technology eliminates the problem of long die changeovers and slower matrix stripping speeds discharge, reducing the waste downtime caused by the broken edges and improving production efficiency.

Rewinder

Rewinder

Servo driven and with accurate tension control; they are smooth, reliable and capable of handling a wide range of substrates including delicate, perforated or punched products. Our rewinders can be tailored to meet individual needs and create a clear, competitive advantage for any business.

-

Product performance and characteristics:

- Flexible conversion from 20um film to 300g cardboard

- With the drawer structure, the knife roller can be replaced quickly, and the operation is easy.

- Hydraulic pressure, digital display pressure, high stability, easy to remember and repeat operations.(CLTS*)

- Modular design, flexo color group can be added to realize simple printing and die-cutting machine.

- You can choose the self-adhesive labeling and sealing device at the end of the paper roll.

| Maximum paper width | 430mm | Gearing | 1/8”(3.175mm) |

| Maximum printing width | 420mm | Motorization | Servomotor |

| Maximum unwind diameter | 1000mm | Air-pressure | 100PSI(7BAR) |

| Maximum rewind diameter | 600mm/min | Lubrication | Automatic |

| Repeat printing | 203~610mm | Material | Film, paper, label material |

| Repeat die cutting | 279~610mm | Max mechanical speed | 200m/min |