Get Support

123-456-789-10

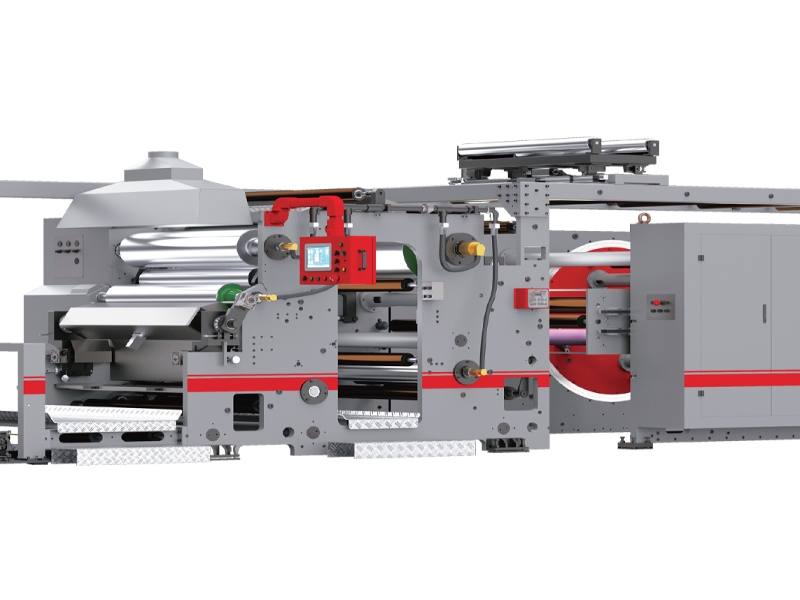

KINGKONG 1650MM , High speed hotmelt coating and Lamination machine :

- Two (2) unwind for facestock and liner including :

Dual wall frame of 60 MM thickness

Maximum Unwind diameter : 1650 mm

Maximum web width : 1200 mm

Maximum mechanical speed : 200 m/min

Material : 40-300 gsm

Close loop tension control with dancing roll load cell

Tension range : 0-80KG

Web guide

Rubber cylinder for changing the rolls

Cutting knife

Core chuck 3 inch or 6 inch

Two (2) Web Guides , including:

Electronic web guide for opaque and clear material, pneumatic splicing table

AKO High precission hotmelt coating station including :

AKO slot -die coating head with rotating bar

Special designed coating head with rotating bar in front of the coating head for paper and film

Minimum coating weight of 13-25 gsm depending on the material

Good coating accuracy of less than +/- 5% ( when coating weight between 15-25gsm)

Rubber rollers and cooling cylinder for lamination

Coating weight measuring scanner : IR system to measure coat weight of adhesive in-line during the production, mounted on rail with automatic movement .

2 Melters with a capacity of 600 KGS for each

One Turret non-stop rewinding Unit for Laminated material including :

Dual wall frame of 60 MM thickness

Maximum Unwind diameter : 1200 mm

Maximum web width : 1650 mm

Maximum mechanical speed : 250 m/min

Close loop tension control with dancing roll load cell

Tension range : 0-80KG

Web guide

Rubber cylinder for changing the rolls

Cutting knife

Core chuck 3 inch or 6 inch

Chillers included

CE standard